Frequently Asked Questions

Frequently Asked Questions

MachineTek was formed in 1992 to perform the specialized and demanding process of honeycomb and foam core fabrication for the aerospace industry. Thirty years later, under the same ownership, continuously adding capabilities to match ever-changing requirements, MachineTek remains focused on composite core fabrication.

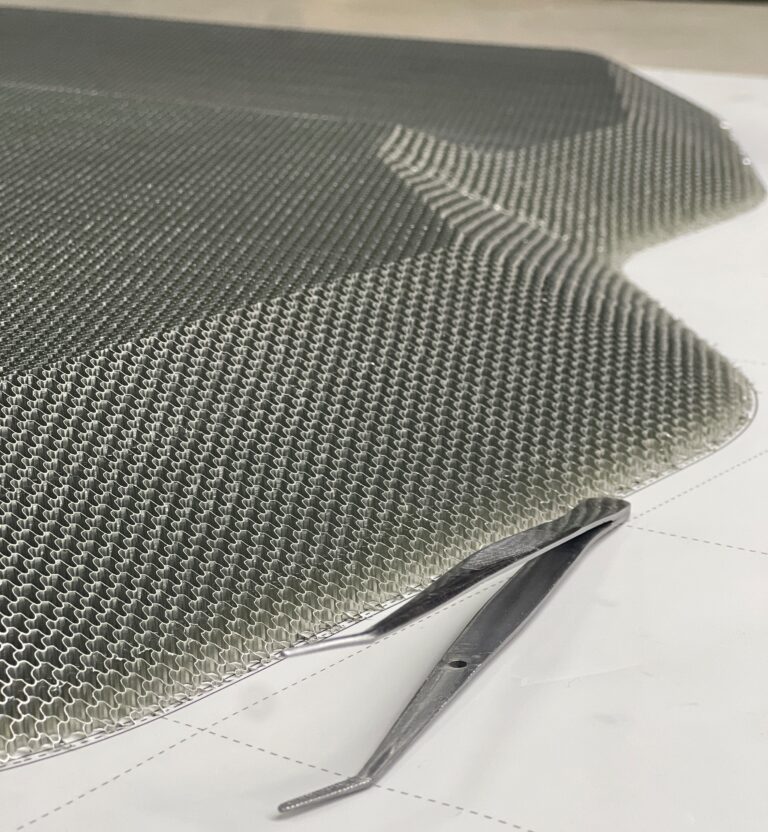

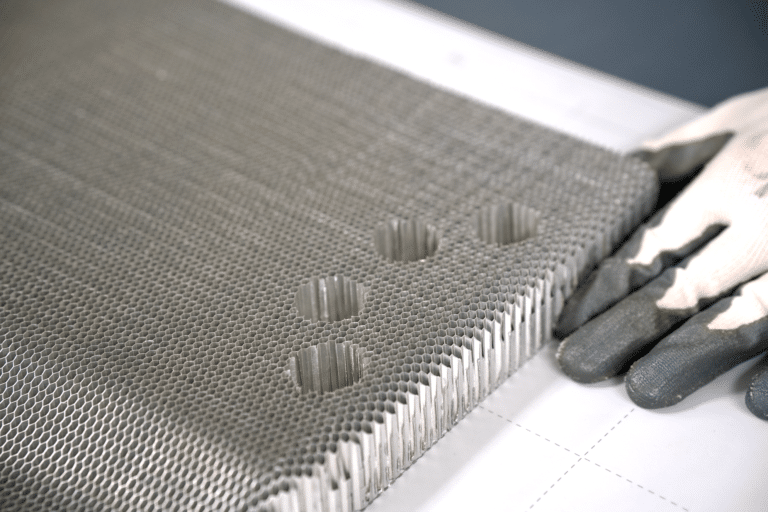

MachineTek specializes in fabrication of honeycomb and foam core components for aerospace and defense applications. Our services include precision profiling, heat forming, bonding, potting of core materials, panel machining, fixture design and fabrication, and engineering support.

MachineTek primary focus is on the aerospace, and defense industries. However, we are not limited to these sectors. Race cars, racing boats, and other users of precision composite cores and panels have all benefitted from MachineTek’s services.

We work primarily with structural honeycomb materials, including aluminum and aramid, as well as specialty foam core materials. MachineTek also machines bonded composite panels with skin materials such as aluminum and carbon fiber.

MachineTek does not produce raw material. Instead, MachineTek procures aerospace-grade honeycomb and foam material from qualified source which meet the exact requirements of each customer program. MachineTek can utilize conforming material provided by our customers.

MachineTek maintains ISO 9001:2015 AS9100 certification and adheres to NADCAP-certified production processes. MachineTek has also been qualified by most prime and sub-prime aerospace manufacturers for various processes relating to honeycomb and foam core fabrication. Moreover, our registration with SAM, ITAR, and the U.S./Canada Joint Certification Office underscores our commitment to regulatory compliance.

MachineTek adheres to rigorous quality control standards and processes. Our certifications require periodic, comprehensive audits by independent certification bodies, ensuring we consistently meet stringent industry requirements. Our quality management team is trained and qualified to perform product inspections, acceptance, and release of parts on behalf of major aerospace corporations.

The standard tolerance for honeycomb surface and edge profile is +/- . 030” with a standard thickness tolerance of +/- . 005.” Tighter tolerances are achievable dependent on core material, density, and cell size. Our program and engineering teams can assist in design analysis to help you understand what is achievable for each type of core material.

MachineTek’s facility is equipped with advanced machinery, including large-envelope 5-axis CNC routers, traditional vertical mills, Coordinate Measuring Machine, a computer-controlled oven, and forming rollers along with specialized tools that allow us to handle a variety of fabrication processes with precision and efficiency.

MachineTek has a large Wisconsin Oven that is certified to AMS 2750F. Thermocouple connections enable precise monitoring of temperatures on and within heating fixtures and parts. Vacuum connections allow vacuum-bagged parts to maintain vacuum throughout the oven cycle. Network connectivity allows capturing multiple channels of data (thermocouples, vacuum transducers, and other parameters) for real-time and historical analysis and to provide finished part documentation. We can provide a documented record of the full oven cycle that your parts undergo from ramp-up, to soak, to ramp-down.

MachineTek’s team is dedicated to providing responsive customer service, ensuring we meet and exceed our customers’ expectations of part quality, timely delivery, and value. We offer comprehensive inquiry, program, engineering, and shipping support to assist with the fabrication and delivery of parts. If the scope of work is outside our capabilities we have a extensive list of suppliers that may be able to support our customers’ requirements.

While honeycomb and foam core fabrication may initially appear simple, the reality is this unique process requires specialized tooling, fixtures, machinery, programming, and other than conventional manufacturing methods. We produce parts to your required specifications and tolerances. MachineTek’s in-house tooling and fixture design capabilities allow production of components requiring two-sided machining or requiring heat forming. Our engineering team is trained and experienced in making suggestions for approaches that can fabricate parts more cost-effectively.

Unlike many competitors, MachineTek has always supported new customers and new programs, even during early-stage prototyping and initial low-volume production. Our commitment to outstanding customer service means we take on small jobs when necessary to allow even our smallest customers to succeed and grow. At the same time, MachineTek excels in supporting production programs involving regular monthly deliveries.

While job complexity greatly affects lead times, material availability is often the main driver of lead times. Once an order has been accepted and raw material received, typically lead times are 4-6 weeks. When machine time and material are available, we have turned jobs around in less than one week. MachineTek will always go the extra mile to meet our customer needs.

You can contact MachineTek through our website’s contact page, email ([email protected]), or phone (760-438-6644). We are committed to providing prompt and helpful responses to all inquiries.

Yes, we are always looking for talented individuals to join our team. Please visit our website’s employment page for current job openings and application details.