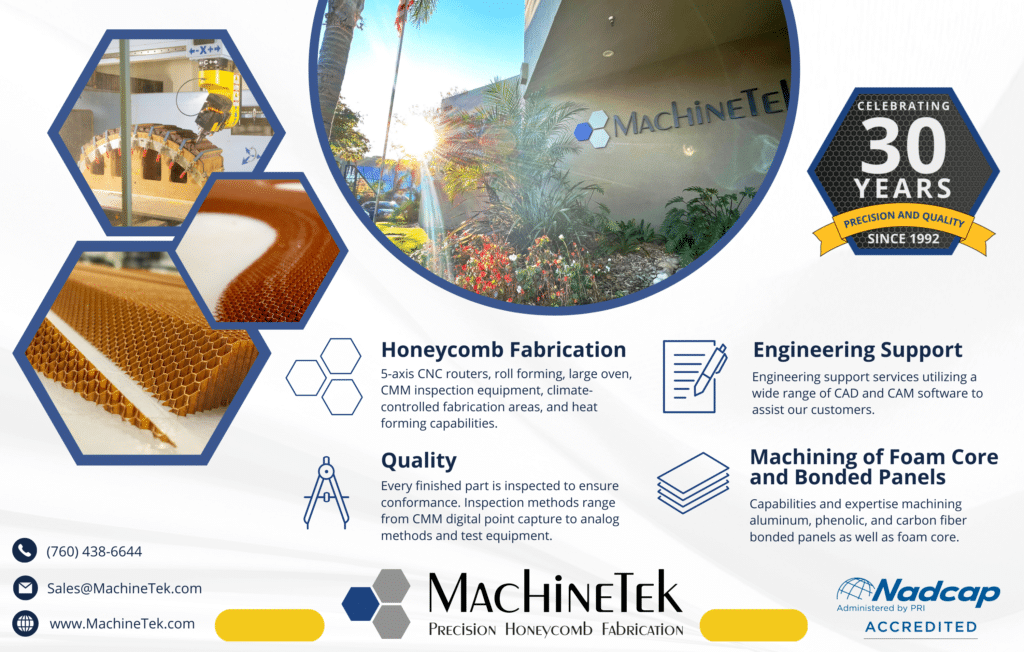

MachineTek's Journey in Aerospace Innovation

When Kevin Darroch co-founded MachineTek in 1992, he saw an opportunity to meet growing demand for fabricated honeycomb and foam core components.

Since then, global aerospace composites markets have grown dramatically, driving the demand for lightweight core components.

Those thirty-three years of specialized experience have positioned MachineTek as a leader in precision honeycomb and foam core fabrication.

A Background Rooted in Precision and Passion

Kevin’s path to leadership reflects a rare blend of technical expertise and personal connection to aerospace. He has worked in every aspect of the process—from flying military fighter aircraft to fabricating the first core component by hand. His service as a U.S. Air Force officer instilled in him the discipline and strategic thinking necessary to excel in such a demanding industry.

“My flying experience gave me a deep appreciation for the precision required in aerospace. Every part, every cut, every bond matters,” Kevin notes. Today, this philosophy permeates MachineTek, ensuring the company’s products meet the most stringent industry standards.

As the aerospace market continues to expand, fueled by innovations in commercial aviation, space exploration, and emerging eVTOL vehicles, MachineTek has remained at the forefront. Industry titans rely on partners like MachineTek to meet the rising demand for fabricated honeycomb and foam parts while navigating complex production challenges.

Kevin observes, “Whether we’re forming core part for space exploration or splicing materials for commercial aviation, our clients trust us to deliver quality parts on time, every time. In aerospace, there is no room for error.”

Core Challenges

The challenges of honeycomb and foam core fabrication often bring customers to MachineTek struggling to produce quality parts in-house. Once customers experience MachineTek’s expertise and reliability, they rarely leave.

“We acquire customers when they face issues—whether it’s poor-quality outputs, missed deadlines, or capacity constraints. But what keeps them coming back is our consistent ability to deliver quality parts and great customer service,” Kevin explains.

With capabilities that include machining, bonding, and forming, as well as certifications like AS9100, NADCAP and ITAR, MachineTek provides the level of quality and repeatability that ensures customer satisfaction. Outsourcing to MachineTek allows manufacturers to focus on their core competencies while relying on a trusted partner to meet their fabrication needs.

Continuous Improvement

At the core of MachineTek’s philosophy is a commitment to continuous improvement. Whether it is adopting new technologies, refining production processes, or expanding capabilities to meet emerging market needs, MachineTek never stands still.

“As the aerospace industry evolves, so do we,” Kevin affirms. “Continuous improvement isn’t just a business strategy; it’s our way of ensuring we stay ahead of the curve, deliver value to our customers, and support growth of the industry.”

From innovations in eVTOL to the ongoing demand for lightweight, sustainable materials, MachineTek is prepared to meet the challenges and opportunities of the future.

Partner with MachineTek for Precision and Reliability

As aerospace manufacturers face increasing demands, the need for precision and expertise in honeycomb and foam core fabrication has never been greater. Under Kevin Darroch’s leadership, MachineTek continues to deliver the innovation, quality, and customer service that allows the world’s top aerospace manufacturers to achieve ever-greater heights.